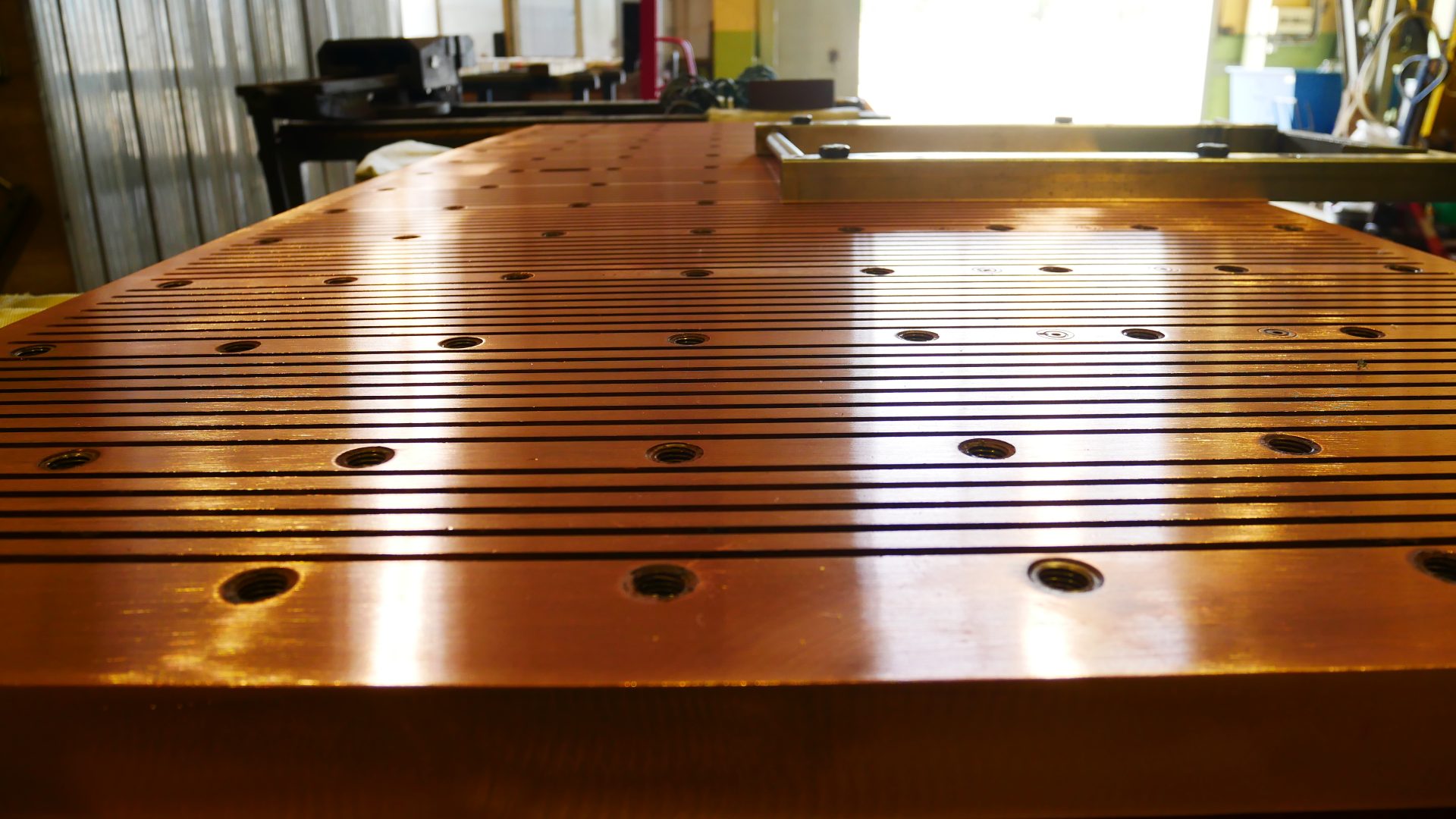

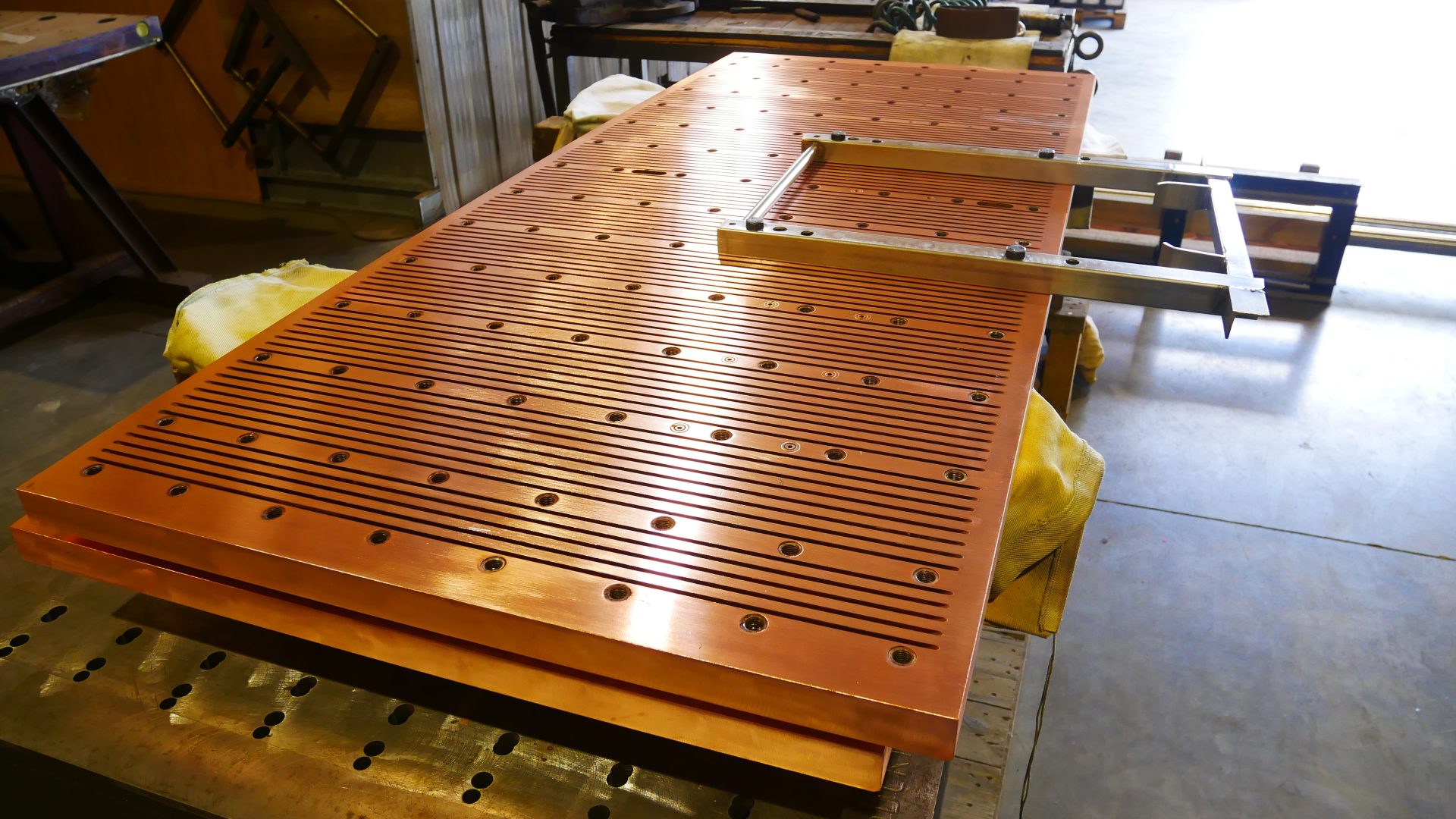

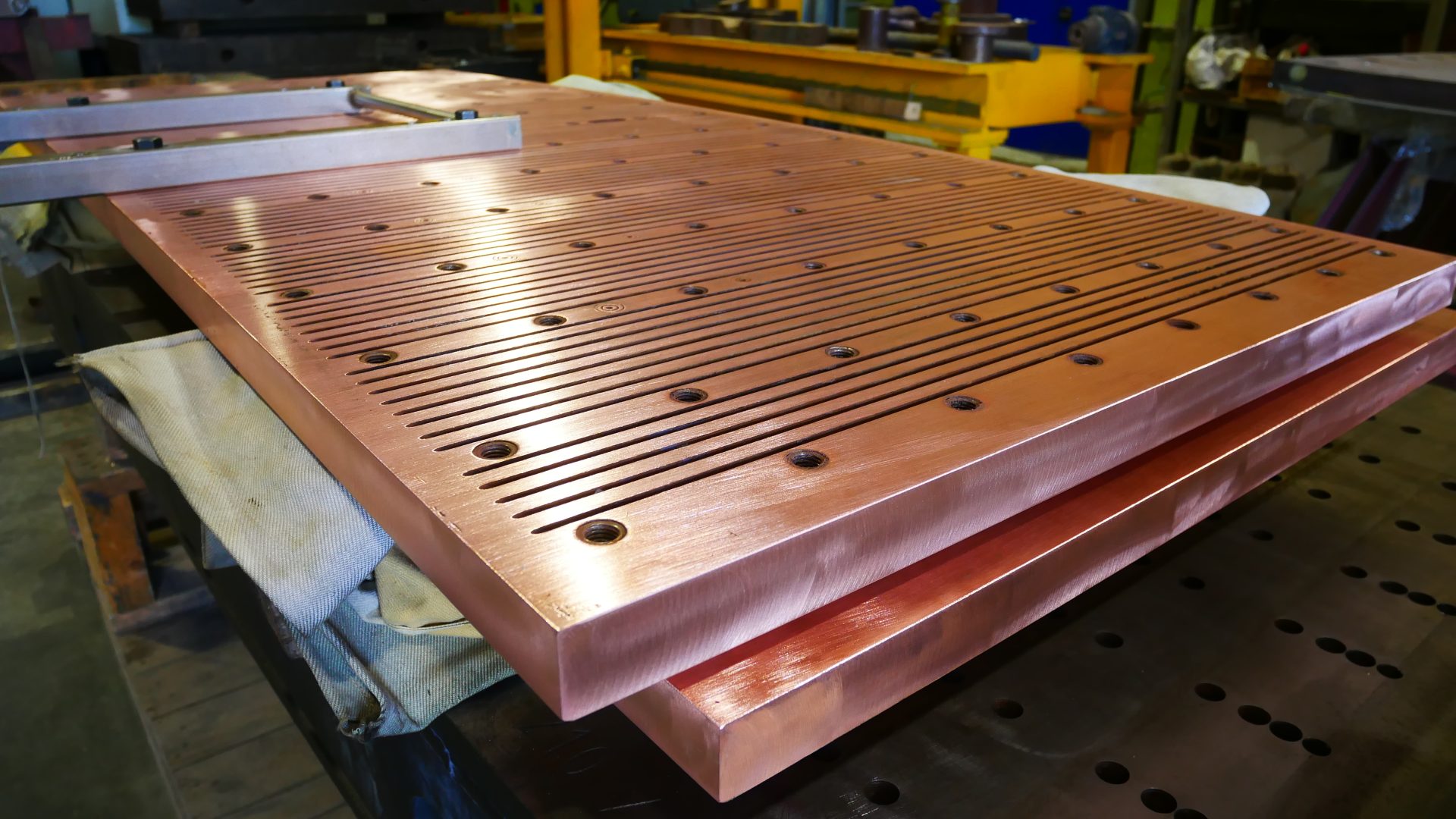

The electroplating section carries out the repair and restoration of the worn layer of the walls of continuous casting machine (CCM) moulds by electroplating with nickel or nickel-cobalt.

The section is equipped with:

• Two nickel plating baths and one nickel-cobalt plating bath

• A 200-tonne press

• A plano-milling machining centre

The stages of plate repair include:

• Cleaning and inspection of used plates

• Straightening of the plates on the press

• Hydraulic testing (for copper walls connected to steel ones)

• Machining of the working surface of the plates before coating

• Dye penetrant inspection

• Application of Ni or NiCo coating to the working surface

• Machining of the working surface of the plates after coating

• Product quality control, including documentation (measurement reports)

• Packaging